ÜRETİM

MALZEME SEÇİMİ

Her valf tappeti için olağanüstü dayanıklılık, hassasiyet ve performans sağlamak amacıyla yüksek kaliteli hammaddeler titizlikle seçilmektedir. Bu kritik ilk adım, otomotiv uygulamalarının sıkı gereksinimlerini karşılayan en kaliteli metal ve alaşımların temin edilmesini içerir ve tüm üretim süreci için sağlam bir temel oluşturur.

DÖKÜM SÜRECİ

Erimiş metal, son teknolojiye sahip tesisimizdeki dökümhanede uzmanlıkla dökülür ve şekillendirilir. Burada yetkin teknisyenler, her bir ön tappet formunda homojenlik ve yapısal bütünlüğü sağlar. Bu aşama, yılların tecrübesinden yararlanarak, sonraki işlemler için hazır, sağlam dökümler üretir.

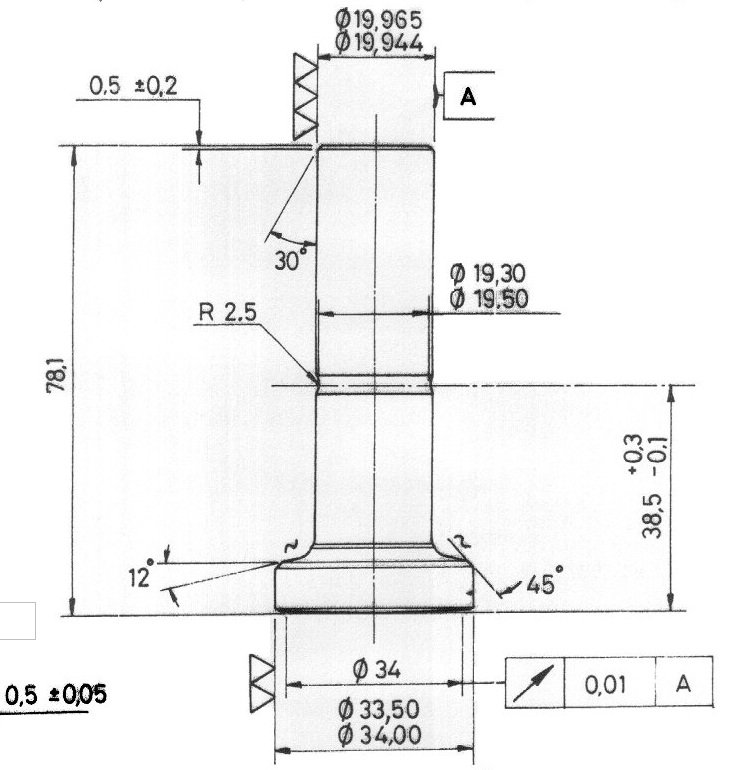

İŞLEME VE ŞEKİL VERME

İleri CNC makineleri, dökümleri titizlikle işleyerek, pürüzsüz yüzeylere ve hassas ölçülere sahip kesin bileşenler haline getirir. Bu süreç, optimal işlevsellik için gereken yüksek toleransları sağlamak amacıyla birden fazla kesme, taşlama ve parlatma aşamasını içerir.

ISIL İŞLEM

Bileşenler, özel tesisimizde titiz bir ısıl işlem sürecine tabi tutulur; bu işlem, parçaların dayanıklılığını, sertliğini ve aşınma direncini artırır. Bu aşama, tappetlerin yüksek performanslı motorların zaman içindeki taleplerine dayanabilmesini sağlar.

KALİTE KONTROL

Her tappet, son teknoloji kullanılarak çatlak kontrolü ve sertlik testinden geçirilir; bu sayede milyon parça başına yalnızca 3 adet gibi etkileyici bir düşük hata oranı korunur. Bu titiz kalite kontrol, üretilen her birimde güvenilirlik ve müşteri memnuniyetini garanti eder.

SON MONTAJ VE AMBALAJ

Tamamlanan tappetler özenle monte edilir, son bir kalite kontrolünden geçirilir ve güvenli bir şekilde paketlenerek sevkiyata hazırlanır. Bu aşama, tesisimizin aylık 200.000 adetlik etkileyici üretim kapasitesine ulaşmasını sağlar. Ayrıca, ürünlerin OEM’lerin ve global pazarların ihtiyaçlarını verimlilik ve hassasiyetle karşılamaya hazır olmasını garanti eder.