oygarsan HIGH QUALITY VALVE TAPPETS

PRODUCING HIGHEST QUALITY TAPPETS SINCE 1972

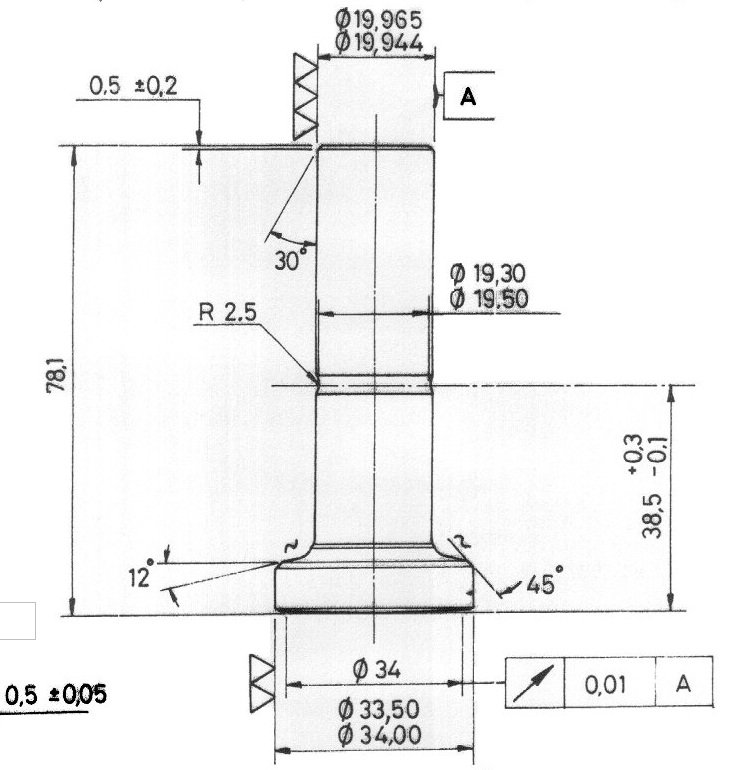

Over 100 different tappet types available

For Oem and Aftermarket

“Every part is individually inspected for quality assurance.”

OYGARSAN Tappet Ltd. was established in 1972 as a family-owned company.

The company was founded with the purpose of manufacturing tappets for automotive OEMs and After Market suppliers.

Our facility is fully integrated and exclusively specialized in this field, featuring its own foundry and heat treatment plant.

At our plant in Istanbul, Turkey, each part produced undergoes individual crack inspection and hardness testing.

As a result, according to the reports of our OEM customers, the defective product rate in our production is as low as 3 parts per million.

Our monthly production volume is 200,000 units, of which 35% is supplied to OEM companies, while our export rate stands at 40% production but also produces OEM within Turkey.

Why OYGARSAN

FACTORY

At OYGARSAN Tappet Ltd., established in 1972, production is a fully integrated process specialized in manufacturing high-quality valve tappets. Located in Istanbul, Turkey, the facility includes its own foundry and heat treatment plant, producing 200,000 units monthly. With 35% supplied to OEM companies and 40% exported, each part undergoes rigorous crack inspection and hardness testing, achieving a defect rate as low as 3 parts per million.

Raw metal preperation

.

Machınıng and HEAT TREATMENT

Qualıty controL

Descoperă experiența captivantă la winmasters romania și bucură-te de jocuri de cazino de top!

Unlock exciting opportunities with the Playamo casino bonus code and elevate your gaming experience in Australia today!